An innovation in chromatography for efficient removal of polyphenols in beer stabilisation by combining a novel PVP modified resin in Controlled Stabilisation Systems.

Beer stabilisation is a critical process required in modern brewing to remove undesirable haze formed during storage due to precipitation/aggregation of haze active (HA) compounds. This provides the beer clarity, stability over time and quality. There are different methods that breweries adopt to achieve haze removal such as the use of polyvinylpolypyrrolidone (PVPP), silica gel, enzymes and cold stabilisation to manage haze formation caused by protein-polyphenol complexes. The chromatography approach by using a polyvinyl pyrrolidone (PVP) modified resin allows it to run a very clean, automated process, where the resin remains in a column and can be regenerated efficiently. This article presents an advance in this technology with a PVP functionalised agarose resin used in Controlled Stabilisation Systems (CSS), regenerated for 1,000 cycles and stable to sanitisation.

Introduction

Beer has played a vital role in human culture for centuries, evolving from a handcrafted beverage to a globally industrialised product influenced by consumer preferences and scientific advancements. Clarity and stability are essential requirements for industrial breweries, allowing for extended shelf and transportation stability, and importantly from a consumer point of view, have a consistent taste and aspect. While haze is integral to certain beer types, such as wheat beers, clarity is often viewed as a sign of freshness and quality1,2.

Haze is primarily arising from protein-polyphenol complexes3. Polyphenols and proteins, naturally derived from malt and hops are indispensable to the organoleptic and biochemical properties of beer. The phenolic compounds significantly influence flavour, aroma and stability, and act as natural antioxidants protecting against oxidative damage6. Tannins, a subclass of polyphenols, contribute to the body and mouthfeel of specific beer styles4,5. However, polyphenols also interact with proline containing proteins to form colloidal complexes that lead to haze, a process exacerbated by temperature fluctuations, emphasising the need for effective stabilisation7,8.

Current stabilisation practices focus on reducing haze by targeting its main precursors: polyphenols and proteins. One common method involves using PVPP, an adsorbent with strong affinity for polyphenols. While effective, excessive PVPP can remove beneficial polyphenols critical for flavour and antioxidant properties. Silica-based adsorbents help with protein-induced haze, but lack selectivity and are often used alongside PVPP.

Alternatively, enzymatic stabilisation hydrolyses haze-sensitive proteins, but it may require additional techniques to tackle polyphenol-induced haze effectively10.

Chromatographic materials, such as those incorporating cross-linked PVP on engineered supports, have shown promising results in beer stabilisation, with polyphenol adsorption rates reaching 34-55%, and good regeneration properties, offering a sustainable solution for beer stabilisation11.

Effective beer stabilisation must balance sensory and functional properties for long-term stability. Over-treatment can deplete essential flavour and antioxidant compounds, while under-treatment may cause colloidal instability. Combining stabilisation techniques with precise brewing process control ensures optimal product quality and extended shelf life 12,13.

Discussion

Sunresin’s innovative PVP-functionalised resin, Seplife® K602FF/CSS3.0, marks a significant advancement in brewing stabilisation technology, offering numerous advantages, including cost savings, scalability, and rapid implementation compared to other PVPP solutions.

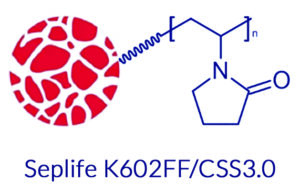

At its core, Seplife K602FF/CSS3.0 was developed using patented advanced cross-linking and functionalisation technologies 14 for optimal performance of the PVP active groups (Figure 1).

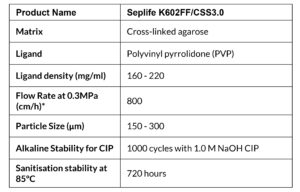

Sunresin’s methodology created an effective binding matrix for targeting polyphenols in beer, with minimal undesired interactions. Table 1 shows the characteristics of the Seplife K602FF/CSS3.0.

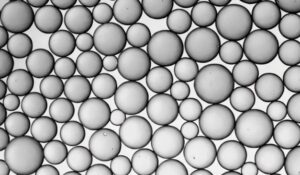

CSS3.0 beads.

The resin appears as perfect spherical beads that can be easily packed in any chromatography system (Figure 2).

A contact time of a few seconds is enough to retain beer polyphenols by adsorption, which are then removed from the resin during regeneration. Neither substances are dissolved in the beer nor particles released to the beer during the beer stabilisation treatment.

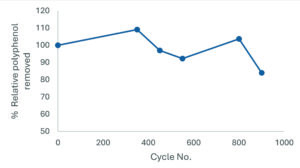

A key performance characteristic of Seplife K602FF/CSS3.0 is its stability for a minimum of 1,000 polyphenol removal cycles, along with the corresponding cleaning-in-place (CIP) and sanitisation steps.

Figure 3 shows the results obtained in forced ageing conditions performed using the resin packed in chromatography column treated with commercially available Snow beer (Snowflake Brewing) at a contact time of <1min, followed by 45 min CIP treatment with 1M NaOH after each cycle. The resin maintained its initial polyphenol removal capacity up to the final test.

from commercial Snow beer during forced ageing test

including CIP with 1M NaOH.

Stability to sanitisation is another key characteristic of the resin; its stability to 85ºC temperature for 720 hours without change in performance is shown in Figure 4. The total polyphenol content in beer was measured using the Analytica-EBC Method 9.11 Total polyphenols in beer by spectrophotometry.

From a regulatory point of view, Seplife K602FF/ CSS3.0 is compliant with Regulation (EC) No 1935/2004 for food-contact materials, ensuring safety and reliability during use.

Importantly, Seplife K602FF/CSS3.0 is compatible with the Handtmann Controlled Stabilisation System (CSS). This compatibility extends to different brewing processes, making it suitable for various beer styles and formulations. The typical CSS radial flow columns packed with Seplife K602FF/CSS3.0 are available for installations from 20 hl/h up to 1000 hl/h. Figures 5 and 6 show examples of CSS systems installed and operational at specified breweries.

Typically, CSS consists of one or several modules completely filled with the resin and run in a fully-automated mode, allowing for precise control over the stabilisation parameters, enhancing the efficiency and effectiveness of the stabilisation process when using Seplife K602FF/CSS3.0. The resin is permanently retained between an inlet and an outlet screen and filtered, unstabilised beer flows through the CSS module. This system has reduced environmental impact due to the small mixed phase volumes and low consumption of water and CIP solution.

From an economic point of view, the CSS system due to its module design is characterised by comparatively low investment costs, while the Seplife K602FF/CSS3.0 filling the module is employed for more than 1,000 cycles, without any loss or mechanical damage. At the end of life, the resin is removed from the CSS module and replaced by a fresh one.

In comparison, the PVPP is added in 20 to 50g/l and can be regenerated when beer processing exceeds 200,000 hl/year. However, each cycle results in up to 3% PVPP loss with some PVPP particles being retrieved in the beer as microplastic.

This highlights that CSS system combined with Seplife K602FF/CSS3.0 resin provides a cost effective, reliable and consistent technology, in line with the modern quality and safety requirements of the beer industry.

Conclusion

Sunresin’s Seplife K602FF/CSS3.0 resin is specifically designed for polyphenol removal in beer, addressing the evolving needs of the modern brewing industry. It exhibits excellent chemical and physical stability in accelerated ageing tests and is well-suited for use in CSS systems. It is commercially available from Handtmann in batch size 300-1000L with a short delivery time. Seplife K602FF/CSS3.0 is compliant with food regulations and can be safely used without risks of leaching or contamination. Technical support will facilitate installation of resin in any equipment for easy product employability. The combination of Seplife K602FF/CSS3.0 and CSS systems offers advantages in terms of quality, scalability, food compliance and economical savings thanks to high automation and continuous processing.

References

1. Bamforth CW. 125th Anniversary Review: The Non-Biological Instability of Beer. Journal of the Institute of Brewing 2011;117(4):488–97.

2. Vanderhaegen B, Neven H, Verachtert H, Derdelinckx G. The chemistry of beer aging – a critical review. Food Chemistry 2006;95(3):357–81.

3. Jongberg S, Andersen ML, Lund MN. Characterisation of protein-polyphenol interactions in beer during forced aging: Protein-polyphenol interactions in beer haze. J Inst Brew 2020;(126):371–81.

4. Carvalho DO, Guido LF. A review on the fate of phenolic compounds during malting and brewing: Technological strategies and beer styles. Food Chemistry 2022;372:131093.

5. Šibalić D, Planinić M, Jurić A, Bucić-K ojić A, Tišma M. Analysis of phenolic compounds in beer: from raw materials to the final product. Chem Pap 2021;75(1):67–76.

6. Habschied K, Loncarić A, Mastanjević K. Screening of Polyphenols and Antioxidative Activity in Industrial Beers. Foods 2020;9(2):238.

7. Leiper KA, Miedl M. Colloidal stability of beer. In: Beer. Elsevier; 2009. p. 111–61.

8. Eastmond R, Gardner RJ. Effect of Various Polyphenols on the Rate of Haze Formation in Beer. Journal of the Institute of Brewing 1974;80(2):192–200.

9. Bamforth CW. Beer Haze. Journal of the American Society of Brewing Chemists 1999;57(3):81–90.

10. Cimini A, Moresi M. Towards a Kieselguhrc and PVPPcFree Clarification and Stabilisation Process of Rough Beer at RoomcTemperature Conditions. Journal of Food Science 2018;83(1):129–37.

11. Maloisel J-L, Sondermann T, Lind O. Stabilisation of fermented beverages. 2016;(Patent: WO 2015/080657 Al):29.

12. Mastanjević K, Krstanović V, Lukinac J, Jukić M, Vulin Z, Mastanjević K. Beer–The Importance of Colloidal Stability (Non-Biological Haze). Fermentation 2018;4(4):91.

13. Mitchell AE, Hong Y-J, May JC, Wright CA, Bamforth CW. A Comparison of Polyvinylpolypyrrolidone (PVPP), Silica Xerogel and a Polyvinylpyrrolidone (PVP)- Silica Co-Product for Their Ability to Remove Polyphenols from Beer. Journal of the Institute of Brewing 2005;111(1):20–5.

14. Li C, Li Y, Liu L, Wang K, Wang M. A chromatography medium for removing polyphenols and a preparation method thereof. 2024; (Patent: CN117772162A):6.