Corporate Responsibility

It’s not easy being green 15th July 2023

By Richard Ward, Business Director of Airedale Chemical

Sustainability has made its way to the top of every company’s agenda and the intention of becoming carbon neutral or even reducing a carbon footprint can seem like a mammoth and unending task.

At Airedale Group in Keighley, we are continuously looking for ways to improve our environmental credentials and have begun working with specialist consultants to understand, monitor and reduce the impact we have on the environment as every step can contribute to a greener chemical industry.

It can seem daunting when almost every aspect of operations is under examination. However, it’s important to accept that this is a journey and there’s no quick-fix, but every step, no matter how small, brings us closer to a more sustainable business and a greener future for everyone.

![]()

![]() We have already put in place a series of measures and projects, but are prepared for a long journey ahead to reach our targets. £40,000 has already been invested in specialist equipment, which will not only contribute to modernising the site, but will also increase our efficiency and introduce a circular economy to our operations.

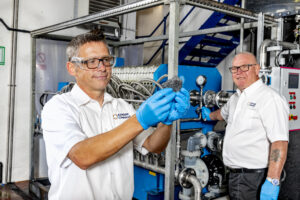

We have already put in place a series of measures and projects, but are prepared for a long journey ahead to reach our targets. £40,000 has already been invested in specialist equipment, which will not only contribute to modernising the site, but will also increase our efficiency and introduce a circular economy to our operations.

This latest innovation removes carbon from the waste product of one of our customers in the activated carbon manufacturing industry, which uses it to remove impurities from food and beverages, pharmaceuticals, chemicals and other liquids. The waste from these processes is reduced significantly, reclaimed and re-used in cleaning solutions, fertilisers and paper products.

Our waste has been halved by the process and it has significantly increased the amount of product that is recovered and re-used in a system that we believe is the only one of its kind in the UK.

It is a fantastic piece of engineering, which has been specially designed for our purposes and not only allows us to reclaim useable products from what would have otherwise been wasted, but also allows us to gain a saleable product from unwanted material.

The knock-on effect from schemes like this is that we are improving the sustainability profile of our customers, who also benefit from our collective goals of utilising recovered products without having to spend resources on the recycling process.

Other on-site projects implemented recently include a 20 metre deep bore hole, which has eliminated the need to draw drinking-quality water for use in our operations from the local supply and has also reduced our overall consumption of water by more than two-thirds.

When the opportunity arose for us to source the water used in our chemical processing plant from within our existing boundaries, it was an easy decision to make, which has led to us outsourcing over 30% less water.

The project required us to work closely with the Environment Agency to ensure the correct licensing agreements and practices were in place and the relationship will be an ongoing one, with monitoring and inspection of the operation being continuous to ensure that all standards are met.

Again, we are leading the way as the first business in Yorkshire to install such a system and one of just a handful in the country putting this type of operation in place to help reduce our carbon footprint.

An investment of £200,000 has also been made in solar panels and these now generate 25% of the electricity used on site, significantly reducing our energy consumption and continuing the reduction of our environmental impact.

Whilst we’re incredibly proud of the initiatives we have implemented in order to minimise the effect we have on the environment, we acknowledge that this is just the start and we have much more work to do in our journey to reduce our carbon footprint. Working with industry leading specialists, we are investing significant time and resources in ensuring we are doing all we can to be as environmentally-responsible as possible.

This journey begins with a collation of all our activities and their impact on the environment alongside the activities of our suppliers and customers, from on-site emissions to employee commuting distances.

To truly understand our impact we’ve considered every aspect of our operations and the considerations expand beyond sustainability to encompass all the elements of environment, social and governance (ESG).

The process has taught us that we need to look beyond the obvious impact from things like carbon emissions and waste levels to the sustainability of our procurement practices, our building standards and even our training programmes and management systems.

Key to our success will be the involvement of the whole team and ensuring that they understand and believe in what we’re doing. Site-wide workshops will unite employees of every department in a single cause and strengthen our efforts to become a more sustainable business. We’re looking forward to embracing the journey, as well as celebrating the targets we achieve.

______________________________________________________________________________

*Director of Airedale Group, a multi-service chemical specialist providing products to an extensive range of market sectors across the UK and Europe.