Water Treatment

Odour control with geo-membrane systems 5th August 2019

By Sarah Harding, PhD

Paul Turgeon, CEO of Anue Water Technologies, explains the technology behind geo-membrane systems, and how they can provide

Paul Turgeon, CEO of Anue Water Technologies, explains the technology behind geo-membrane systems, and how they can provide outstanding odour control in the industrial setting.

Earlier this year, Anue Water Technologies launched its customizable geo-membrane products for the entire North American and Caribbean regions. Having already established itself as the leading manufacturer of high-efficiency Ozone and Oxygen systems for the elimination of odour, corrosion and FOG (fat, oil, grease) in municipal and industrial wastewater,1 this addition to Anue’s portfolio of offerings clearly maximizes on the company’s expertise in the area. We spoke to Anue CEO Paul Turgeon about the strategy behind the deal, the technology and its applications in the industrial setting for manufacturers of speciality chemicals.

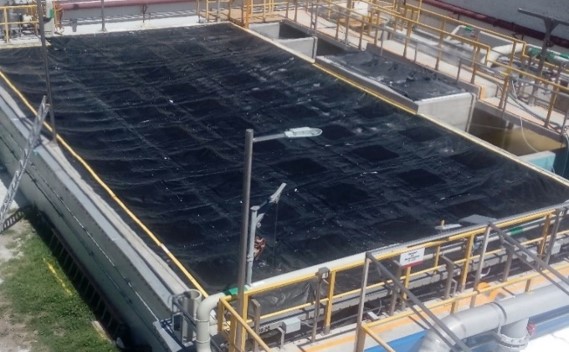

The technology consists of high strength geo-membranes – very low permeability synthetic liners that control fluid migration. These geo-membranes are made from a proprietary material with superior tensile strength and chemical resistance, and they are fitted with pockets containing replaceable filter media. These activated carbon impregnated filters are breathable, allowing air and water to pass through while trapping the odour, and they are custom engineered to fit each application.

Such customization covers physical aspects, such as the shape of the structure containing the odourous wastewater, as well as chemical ones. These detailed specifications could be likened to the ‘secret sauce’ of geo-membrane technology, as the experts at Anue consider the chemistry behind each individual application.

“We use different manufacturing specifications for the speciality carbon filters, depending on the application”, explains Turgeon. “The media can be customized for particle size or extra ingredients, for example, to control particular odours and ensure exceptional broad-spectrum odour control.”

With an ability to remove all odours, including those from sulfide and ammonia build-up, which can be difficult to control, the geo-membranes can be used in practically any application. There has been a lot of early uptake in the food and beverage industry, for example, and geo-membranes are also being used as vent covers in the petrochemical industry to prevent noxious gasses from escaping.

“A lot of sectors – including some in the speciality chemicals industry – have very specific needs from a regulatory perspective,” says Turgeon. “If a plant has regulatory restrictions on what odours it can release, this can be a very specific goal, which can be addressed by geo-membrane technology.”

The geo-membrane technology greatly reduces labour touch and occupational health and safety risks, and it eliminates the need for costly chemicals or scrubber equipment. So much so, that it is reported to pay for itself within 6–12 months. Turgeon cited one real world example in the food and beverage industry, when a Fortune 500 company replaced a scrubber system at a site in Brazil and saved over $240,000 in one year.

The activated carbon filter media is changed every 6–12 months, after which they are simply put into solid waste or incinerated – no special disposal is needed. Carbon is not noxious and has no knock-on products as a result of incineration, so this approach is non-toxic and does not harm the environment. The current disposal method is tolerable, says Turgeon, at least for the time being.

“We’re already looking at more biodegradable materials,” he adds. “At the moment, the efficacy isn’t there, but we are actively investigating this and we’re hoping that in the future we’ll be able to make the systems even more environmentally friendly.”

The technology was first commercialized in 2011 and is already proven with use in 18 countries by major companies and municipalities.

“We’re getting a lot of interest with every application, and the word-of-mouth factor has been pretty impressive,” says Turgeon. “We’ve only had this technology in-house for about 6 months, but we have a significant pipeline of opportunities and an impressive market response.”

Of course, as the renowned experts in Ozone and Oxygen solutions, it is interesting to hear how Anue sees this new technology fitting alongside its existing Ozone and Oxygen injection systems for odour control.

“Sometimes the situational dynamics just don’t fit Ozone and Oxygen because it’s difficult to get power to the site, or because tanks are just holding stagnant materials,” Turgeon explains. “The geo-membranes can be used in remote locations that don’t need power. In the end, it just comes down to what’s the best fit for use and for customer economics.”

“The geo-membrane technology is simple but elegant,” concludes Turgeon. “And it means we have an extra service and product that meets a specific set of needs. It’s relatively early days for us, but we’re expecting the impact of geo-membranes to grow.”

References

1. Turgeon P, Chandler T. Chemicals Knowledge Hub, 1st July 2019: http://chemicalsknowledgehub.com/article/water-treatment/view/ozone-and-oxygen-for-sustainable-odour-and-corrosion-control-/

Contact:

The author of this paper is available and welcomes any questions or comments. He can be reached at +1 760 476 9090 or at info@anuewater.com.