Regulations & EHS&S

Safety First! 23rd May 2018

By David Garner, Chairman of Brenntag’s Global HSE Team

David Garner, Chairman of Brenntag’s Global HSE Team and Senior Vice President Operations Brenntag North America, talks to Chemi

David Garner, Chairman of Brenntag’s Global HSE Team and Senior Vice President Operations Brenntag North America, talks to Chemicals Knowledge about the importance of ensuring process safety tools are consistently and effectively executed throughout an organization.

How have process safety issues evolved for the speciality chemicals industry over the past 20 years?

20 years ago, process safety was not built into the safety culture of many companies and really was more of an afterthought. Typically, there was more of a reactive approach, versus being proactive when it came to process safety.

Today, process safety is at the forefront of everything that occurs within the speciality chemicals industry. The focus of the industry has shifted to being more proactive by identifying things within a process that could go wrong and implementing preventive safeguards to eliminate or mitigate the potential risk. Overall, there is a stronger sense of responsibility for keeping our employees, community and the customers we serve safe.

Thankfully, major accidents are becoming increasingly rare. What do you think have been the main contributing factors to this?

First, many countries have promulgated legislation that defines specific process safety requirements that companies must adhere to, in order to ensure a sustainable operation. Failure to comply has the potential to result in fines or penalties; cessation of operations and a tarnished reputation.

Second, and probably more important, is the advancement in process and engineering controls. Technology advancements now allow for easy installation of alarms, process controls and automatic shutdown systems to ensure process control is maintained.

Third, companies are more willing to share best practices and lessons learned from previous incidents in order to prevent similar incidents from re-occurring.

What prompted the formation of Brenntag’s ‘Safety First’ programme?

At Brenntag, employees are our most valuable resource. We have a legal obligation – and more importantly a moral obligation – to ensure their safety. “We are the safest chemical distributor” is the primary objective of our corporate vision.

Worldwide, Brenntag operates in accordance with the “Safety First” principle as our most important company value. Bottom line – employees should not be apprehensive about coming to work for fear of getting hurt. No matter what else transpires throughout the day, if everyone goes home in the same condition as they came to work, then we have had a great day at Brenntag.

Therefore, safety must be the first thing we focus on when we are evaluating any area of our business. We are bound by the highest standards in the industry and adopt policies which often exceed statutory requirements. We are working continuously to further improve safety within our company. We invest in our infrastructure and train our employees with this goal in mind. Our goal is to achieve a Group accident rate LTIR1Day of below 1.0 by 2020.

How was the ‘Safety First’ programme rolled out globally?

“Safety First” has been Brenntag’s top priority already for a long time, and forms the basis of our global HSE strategy. This encapsulates our principles in the areas of safety, product stewardship, the environment, adherence to laws (compliance) and quality. The global strategy is implemented in the regions as part of their own HSE programmes. Our HSE manuals define processes, procedures and measures that are implemented at our regional sites. Brenntag has a global Quality, Safety, Health and Environment (QSHE) Team that is responsible for developing concepts and rolling out new safety initiatives throughout the organization.

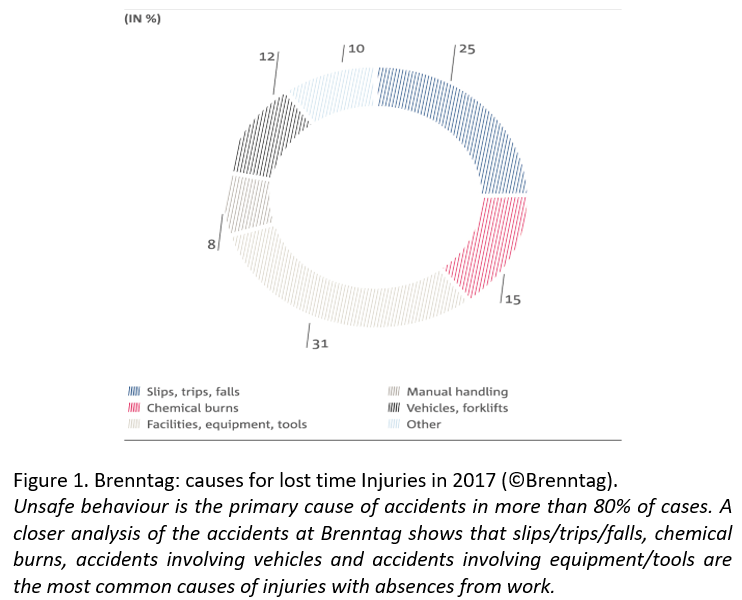

A key element of our efforts to increase safety is the global Brenntag Enhanced Safety Thinking (BEST) programme. It focuses on the safety behaviour of Brenntag employees at all levels within the company, which is the primary cause of accidents in more than 80% of cases (Figure 1).

Various programmes and measures were implemented in the Brenntag regions and national organizations to promote safe behaviour and to correct dangerous behaviour. These centre on regular and extensive communication, greater involvement and motivation of employees and increased visibility of exemplary safety within the company.

What more needs to be done in the speciality chemicals industry to ensure process safety?

The majority of process safety tools are already in existence for companies to be successful in the prevention of incidents. Industry’s primary focus should be on ensuring that those applicable process safety tools are consistently and effectively executed by management and personnel throughout the organization. The majority of specialty chemicals that Brenntag handles are not hazardous, so we don’t have as much knowledge in this area.

Earlier this year, Brenntag Mexico celebrated 10 years of no accidents. Is it a feasible goal for all companies to close the gap to zero accidents?

Achieving zero accidents is no doubt an extremely high bar to set for any organization. However, as demonstrated in Brenntag Mexico, this goal is totally feasible.

Achieving zero accidents within an organization takes proper leadership with dedication, persistence and commitment from all levels of management and every employee within the organization. Regular training for the employees is important in order to raise their awareness of potential hazards and to enable them to work safely. In addition, accidents at work, near misses and similar occurrences need to be recorded and evaluated, and any important conclusions must be communicated throughout the organization.

Although achieving zero accidents is extremely difficult, at the end of the day, it is the only acceptable goal when it comes to the safety of our personnel and the protection of the surrounding community in which we serve.

Interview with:

David Garner, Chairman of Brenntag’s Global HSE Team and Senior Vice President Operations Brenntag North America.

DGarner@brenntag.com

DGarner@brenntag.com