Materials Science

High-tech thermoplastics for the vehicles of the future 18th February 2021

Global speciality chemicals company LANXESS sees new, environmentally friendly forms of mobility as a future-oriented growth segment for its plastic materials and plastic composites business based on its many years of experience and development expertise in the field of plastic components for the automotive, electrical and electronics industries. This article describes how its high-preformance polymers are being developed and engineered to meet the demanding applications of these industry sectors.

Speciality chemicals company LANXESS produces a wide range of high-performance polymers for demanding applications with materials under development for new forms of mobility that are geared to a number of key areas, in particular electrification of the powertrain for vehicles both with and without a driver, and the development of the necessary infrastructures and logistics. The company is also working on new lightweight materials and technologies, including those to help increase the range of electric vehicles, while its lightweight materials play an important role with regard to vehicle weight, improving the reach of vehicles and making them safer. LANXESS materials also have potential application in radar systems to avoid collisions or adaptive cruise control systems.

High Performance Materials business unit

The LANXESS Business Unit High Performance Materials (HPM) offers key industries a wide range of engineering plastic compounds and is supported by global production facilities and an R&D network. Worldwide, more than 1,600 employees work for HPM at 13 locations, making LANXESS a leading supplier of thermoplastic high-performance polymers. The company’s polyamide 6 and 66 grade families Durethan and Pocan have strong potential for growth and innovation and LANXESS produces caprolactam, polyamide 6, polyamide 66, glass fibres and polybutylene terephthalate at production sites in Belgium, Germany, Brazil, China, India and the USA.

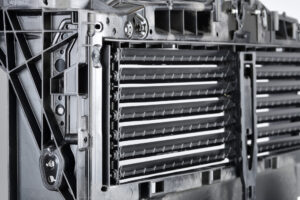

LANXESS has also been developing a wide range of high-tech thermoplastics for the automotive sector, lightweight solutions based on its Tepex-branded continuous-fibre-reinforced thermoplastic composites for brake pedals, as well as structural components for vehicle bodies and blow-mouldable and injection-mouldable polyamide compounds for tanks and hollow parts for the air management of turbocharged engines.

Earlier this year, at the VDI Plastics in Automotive Engineering (PIAE) Congress, which was held virtually due to the COVID-19 pandemic, the company displayed the tank of a BMW Motorrad road machine, which is made from LANXESS’s Durethan BC550Z 900116 DUSXBL thermoplastic. The unreinforced and impact-resistant modified polyamide 6 is injection-moulded into two half-shells, which are welded to the tank by means of hot plate welding. The company says that because of this material, the engines can be manufactured cost-effectively in large quantities despite their complex geometries and that the limit values for fuel emissions through the tank walls are undershot by a considerable margin.

Tepex high-performance composites

LANXESS’s Tepex high-performance composite laminate systems are based on thermoplastic polymers in combination with continuous reinforcing fibres, resulting in exceptionally high-strength and high-rigidity materials that are extremely low in weight. Tepex also enables cost-effective fabrication of parts using processes suitable for mass-production, especially when performed in combination with injection moulding.

These composite materials offer a wide range of properties that make them suitable for use in a variety of applications. The thermoplastic matrix also offers many advantages with regard to processing: it can be formed, welded and overmoulded, while, unlike for metal parts, all functionalities can be created in a single production step, thereby enabling efficient production processes. Tepex is also storage stable and recyclable.

Some Tepex materials are significantly stronger than metal sheets, are almost as stiff, but are also much lighter. The components formed from them also absorb considerably more energy in the event of deformation than comparable metal parts: this has been demonstrated in extensive crash tests.

The potential of Tepex-branded composite materials for use in lightweight applications were also demonstrated by the company at the PIAE Congress, one example being an all-plastic brake pedal developed for a battery-electric sports car. The composite component is about 50% lighter than an equivalent steel construction and meets all load requirements thanks to the tailor-made fibre layer construction of the Tepex insert and local reinforcement using additional tapes. Due to these properties, Tepex materials are already being used in mass production for various structural components in automotive production: prominent examples are the pivoting seat shells for the new Audi A8 or multiaxial, reinforced Tepex for backseat load-through.

Autonomous driving

Autonomous vehicles require a variety of sensors, controllers and displays to meet all control and safety requirements. Durethan polyamides and Pocan polybutylene terephthalate polyester are highly suited materials for connectors and housings and enclosures required for ultrasonic measuring instruments and radar systems can be manufactured from these materials to meet precise requirements. HPM’s engineering plastics can also be used to optimize components for communication systems in traffic management.

Weight reduction is also a key focus in the development of autonomous driving vehicles as lighter designs have lower energy requirements. Such designs are also cheaper and more environmentally friendly. At the same time, new materials must meet the same requirements as existing ones in terms of strength and potential energy absorption and a further example of systematic lightweight design using a Tepex composite is an A-pillar with a 3D hybrid design developed by Porsche for vehicles such as convertibles and roadsters which is being employed for the first time in the Porsche 911 convertible. The A-pillars with hybrid inserts are just as stable in the event of a crash as previous designs featuring high-strength steel tubes, but they reduce the weight of the vehicle body by a total of about five kilograms.

According to LANXESS, Tepex also has “enormous” potential to be applied in structural components and housing parts for high-voltage batteries in electric vehicles. This is due to the flame-retardant properties it displays even without the use of flame-retardant additives in various tests based on established standards. The composite materials used here present a lightweight alternative to aluminium and also enable cost-effective component solutions due to the cost-reducing integration of functions and simple processing without the need for rework in the hybrid moulding method.

Further information

W: https://lanxess.com/en/Company/Corporate-Structure/Business-Units/High-Performance-Materials