Water Treatment

Managing downstream hardness upset in boiler systems 20th December 2018

By Justin Treece, U.S. Water Area Manager, and Ray Gesling, B.S.M.E.

Justin Treece, U.S. Water Area Manager, and Ray Gesling, B.S.M.E. describe a recent case study in which a water technologist and p

Justin Treece, U.S. Water Area Manager, and Ray Gesling, B.S.M.E. describe a recent case study in which a water technologist and pharmaceutical plant engineer teamed up to master and manage downstream hardness upset in a boiler system.

One of the most prominent issues experienced with boilers is the formation of calcium carbonate scale on boiler tubes due to improper calcium levels within the feed water system supplying the boiler. If left untreated this scale, even if only a couple millimeters thick, can cause uneven heating, increased operational costs, and potentially result in premature boiler failure. Often improper calcium levels occur when a feed water softener is not functioning properly, but what if calcium issues are observed on a system with a properly working softener?

After working with their water treatment vendor for three years, a Southern United States pharmaceutical plant was surprised to find all three of their onsite boilers scaled. The plant leaned on the current vendors abilities to identify and diagnose the issues and based on the monthly water analysis reports, the plant’s treatment program seemed to be operating satisfactory. Therefore, plant engineers were understandably confused and frustrated after an open boiler inspection revealed extensive scale formation in all three boilers. The boiler scale and a low return rate were causing increased fuel and operational costs, causing the plant to seek a second opinion.

A U.S. Water representative conducted a plant survey in an attempt to uncover the boiler system issue. At first glance everything looked relatively normal. Surface blowdown controllers located on all three boiler systems had set points within range to run efficiently, and the water treatment vendor at the time was using a solid phosphate/caustic/amine/sulfite chemical program. After reviewing the gauges and sensors on the deaerator and feedwater equipment, U.S. Water’s representative inspected the de-aerator tank and discovered the water temperature was at 170°F, and the pressure was five pounds per square inch (PSI). De-aerator tanks are meant to operate within 3°F of saturation to mechanically reduce dissolved oxygen as low as possible. At 5 PSI, the boiling point of water is increased to 227°F, so one would expect to see at least 220°F. Plant engineers had mentioned they had noticed a steady decline in the temperature over last year.

It is common on newer softener systems to see lower calcium levels in the feedwater downstream of the softener due to improper regeneration settings during setup. On older units, it may be due to a loss of resin capacity. Keeping in mind the formula for Feedwater (makeup + condensate return), this system did not fall into one of those categories. Starting with the basic foundations of proper system operation, the U.S. Water representative used a process of elimination to identify the root cause of the issue. The feedwater softener operation was verified with conductivity and hardness testing and were performing as designed with no hardness present and conductivity of 238 microSiemens per cubic centimeter (µS/cm3). The representative moved to the condensate tank located at the furthest point on the steam system from the de-aerator, and ran the same two tests that were performed on the water softeners and deaerators. The results from the condensate tank revealed a conductivity of 250 µS/cm3 and a calcium hardness of 38 PPM. Conventionally, anything over zero calcium hardness in feedwater indicates an issue with the system that needs to be addressed.

It is critical to check condensate return portions of heat exchangers, as they typically operate as gravity feed systems back to condensate return tanks with little pressure in the lines. City water supply pressures at this location were 40 PSI, so the natural tendency for water to take the path of least resistance will cause an unwanted hardness intrusion back into the condensate return supply. All heat exchangers onsite that were connected to the steam distribution system were also reviewed, allowing the U.S. Water representative and plant engineer to zero in on the hot water distribution system that provided heating for the re-heats on the HVAC system. The hot water distribution was heated from a shell and tube heat exchanger tied into the steam distribution system. A pressure gauge on the hot water side of the system indicated the hot water loop was ten PSI lower than optimal operating pressure. Pressures on closed systems are controlled primarily with the makeup water line and pressure regulator, which prompted the team to review the makeup water bypass where they discovered the valve slightly open. A calcium harness test performed on the condensate return from the heat exchanger revealed calcium levels almost identical to the city water in the area at 40 PPM, but best practice on a properly working pharmaceutical plant should be zero PPM calcium. This was a clear indication that the closed loop system was losing water, being consistently replaced with city feedwater, and sending large amounts of hardness to the boiler system. The U.S. Water representative had identified the root cause behind the system’s scale and low condensate return rate.

U.S. Water’s team partnered with plant engineers to develop and implement a remediation and maintenance plan to mitigate the issue. Unfortunately, the effects of corrosion cannot be undone. However, by implementing the proper treatment plan, plants can prevent continued damage and secure the remaining lifespan of the equipment. In an industry such as pharmaceuticals, disruption of production is extremely costly and has far reaching implications. Heat exchangers are very costly to service and replace, and repairs can take months due to long lead items. When calcium levels are over five PPM, utilizing a chemical solution to control scale is not a feasible or cost-effective approach.

U.S. Water developed a unique solution suited to the pharmaceutical plant’s operational needs. The contaminated condensate was re-routed from the condensate return to the nearest all metal drain line, while system repairs were made. Then boiler setpoints were reduced to increase the rate of solids removal and encourage increased soft water makeup into the boiler system until all traces of hardness were no longer entering the boiler feed water system. Recommendations were also made to increase the bottom blowdowns to at four-to-six times per day to prevent sludge formation from hardening and clogging the blowdown lines. The chemical phosphate program was then adjusted to a Chelant chemical program to remove existing scale and reduce the system’s salt consumption.

The program was enhanced with a proactive, digital solution. U.S. Water’s TowerAssure automation package was introduced for both cooling tower systems, along with boiler blowdown controllers for online monitoring.

The cutting-edge control technology featured several inputs to allow engineers to monitor both boiler and deaerator conductivity, and send instant alarms directly to the facility engineer and U.S. Water representative if either were outside of the desired level. Once coupled with U.S. Water’s daily dashboard, the plant engineer received daily system summaries allowing for complete transparency of the water treatment program.

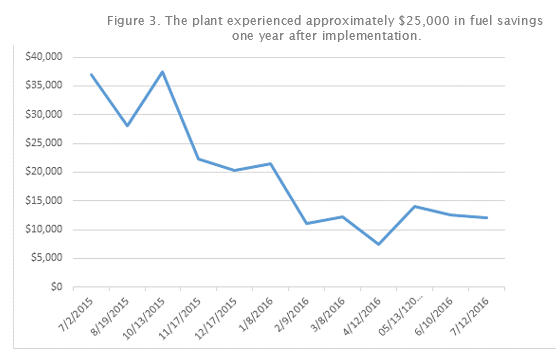

After implementation of the solution, the customer noticed substantial energy savings and improved system efficiency. Both of the cooling tower systems corrosion coupon results started trending down to acceptable levels, and condensate return water quality contained zero hardness. The level of condensate return is steady around 80%, a dramatic increase from less than 28%.

If a boiler system issue does arise, a proactive approach of effective diagnostics and remediation utilizing advanced technologies can ensure the facility is protected. A true partnership between facility engineers and water treatment professionals can positively impact facility operations in terms of equipment reliability, system downtime and operational cost.