Pharmaceuticals

MEETING DEMAND FOR SEMI-SOLID DOSES 28th March 2022

When it comes to the continued growth of Semi-Solid Doses, LGM Pharma believes it takes a CDMO partner to deliver outcomes that may not have seemed possible at the outset.

The most popular form of drug dosage is oral solids. While this is not likely to change any time soon, a younger dosing technology – semi-solid dose (SSD) – is increasingly filling a need that other dosing forms cannot. This has spurred pharmaceutical companies to find innovative ways to use SSDs in order to develop new treatments for a host of diseases and conditions.

While demand for SSDs is rising and the market for them is expected to grow, the development of drugs using this dosing form is not without its challenges. SSDs come with their own specific technical challenges, so companies looking to develop and commercialise SSD-based medications need to consider these when creating their development timelines.

The different forms of SSDs

Semi-solid dosage forms on the market today are administered in three different ways: as a topical form applied to the skin; suppositories that are administered either vaginally or anally; and as chewables taken orally.

Topical semi-solid dosage forms comprise creams, ointments, gels and pastes, with the active drug ingredient penetrating the skin surface or in some instances, the eyes, nasal cavity or mouth. The forms of SSDs include complex multi-phase systems that require detailed rheological characterisation – properties that may meaningfully affect quality and performance. Rheology regards the study of the material flow and deformation behaviour and may be measured by applying an external force (shear-induced deformation) to a sample. Allied to formulation viscosity, elasticity and plasticity, rheological behaviour can also impact product manufacturing, appearance, packaging, long-term stability, dispensing, sensory properties and the in vivo performance. For this reason, rheology assessment can be used to predict batch variability, product aesthetic properties, therapeutic effectiveness and patient compliance – all useful indicators of product quality and stability.

While topical forms are most common, SSDs are also developed as suppositories inserted into the body either vaginally or rectally, allowing body temperature to dissolve the drug product’s exterior, exposing the active pharmaceutical ingredient (API) to be absorbed by surrounding tissue.

Semi-solids can also come in the form of a chewable, another request that LGM Pharma sees quite frequently. The semi-solid chew is ideal for patients who have trouble swallowing solid pills, tablets and capsules, pediatric patients or pets.

The company, a Contract Development and Manufacturing Organisation (CDMO), works with the spectrum of SSDs at its 54,000 sq ft facility in Texas, but chewables and suppositories are its strength. While many CDMOs can manufacture topical semi-solids, few possess LGM’s well-established track record and state-of-the-art filling and sealing technologies needed for suppository and chewable dosage forms. LGM receives a number of new client requests for suppositories and produces some 35 million doses annually.

Addressing SSD challenges to develop a generic drug

A recent project for LGM highlighted some of the considerations drug developers need to consider when working with SSDs. In this case, the client approached the company with an abbreviated new drug application (ANDA) for an oral topical application.

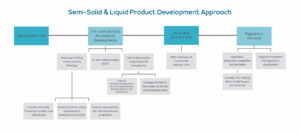

For this project, the process began by reverse engineering the formulation of the reference drug. The maximum allowable quantity for the product’s active ingredient, triamcinolone acetonide, was determined by using the FDA’s Orange Book data files. LGM’s product development approach was based on Quality by Design (QbD) principles, which were leveraged to develop a volume of data to help better understand the balance of all other ingredients in the formulation. This information allowed for the smooth scaling of 500 gramme test batches all the way up to 150 kg commercial volume – while ensuring the integrity of the finished product. These data also provided the backbone of a robust FDA submission that will help the client efficiently proceed with the product’s regulatory review.

However, as noted above, the project was not without its challenges. The first was discovering that the excipient for the product – a plasticised gel for delivery into the mouth – was very difficult to source. After investigating availability with third-party manufacturers, LGM determined that it could not ensure a continuous and cost-effective supply of this critical ingredient.

The solution was to make the excipient in-situ. To accomplish this, the company’s research team scoured the scientific literature and found a reference for formulating the plasticised gel as part of the manufacturing process. It was an exacting process that required holding heated mineral oil within a narrow temperature range while incorporating polyethene at precise mixing speeds to form the plasticised gel and then quickly dropping the temperature while adding the drug’s solid elements.

Using QbD principles, the team developed detailed protocols based on its scientific analysis of the product to ensure the exacting procedure was reproducible, at the highest quality, batch after batch.

A second challenge was packaging the finished product. During manufacture, the product needs to be warm enough for handling on the filling line, but must ultimately cool down enough to become a gel suitable for consumer use. This challenge was heightened by the product’s destination – small, 5 gramme tubes. Through iterative testing, the team found the precise temperature to allow packaging and then subjected the finished product to a battery of QA assessments to ensure its integrity. The product has gone through both accelerated and long-term stability for 36 months and is meeting all the product specifications.

The need to think outside the box is what allowed the LGM team to deliver the results needed for this ANDA. When it comes to the continued growth of SSDs, the company believes it takes deep experience from a CDMO partner – and a willingness to explore solutions pharmaceutical sponsors may not have considered – to deliver outcomes that may not have seemed possible at the outset.

Further information

LGM Pharma

Web: www.lgmpharma.com