Pharmaceuticals

The excipient challenge in ODTs 22nd August 2018

By Carolina Diaz Quijano, Head of Technical Services Consumer Goods at Omya International

Carolina Diaz Quijano, Head of Technical Services Consumer Goods at Omya International, explains how excipient

Carolina Diaz Quijano, Head of Technical Services Consumer Goods at Omya International, explains how excipients for orally disintegrating tablets (ODTs) can contribute to stability, inertness, flowability, compactibility and a pleasant mouthfeel in the final formulation.

Orally disintegrating tablets (ODTs) are designed to dissolve in the mouth within seconds, without the need for water, and it turns out that there is an optimum speed of disintegration. If the water uptake phase is too quick, it is often associated with drying of the mouth. The best sensation is when disintegration starts quickly upon contact with a small amount of saliva and lasts less than 30 seconds.

ODTs can be manufactured using various techniques, including tablet moulding, freeze drying, spray drying and direct compression. From perspectives of cost and simplicity, the preferred method is direct compression. However, disintegration of ODTs produced in this way is limited by the size and hardness of the tablets. The key parameter for directly compressed ODTs is compression force. If it is too low, it may improve disintegration but lead to a friable tablet that is not robust enough for handling. Conversely, a compression force that is too high will result in ODTs that do not disperse properly. An excipient with good compactibility properties is of utmost importance.

The right excipient

Today’s ODT formulators have access to several directly compressible excipient platforms, especially designed for ODTs. The choice of ODT platform is crucial. It must be stable, have a good level of inertness, good flowability and compactibility, and it must contribute to a pleasant mouthfeel in the final formulation. It can be difficult to find a multifunctional excipient that combines these features.

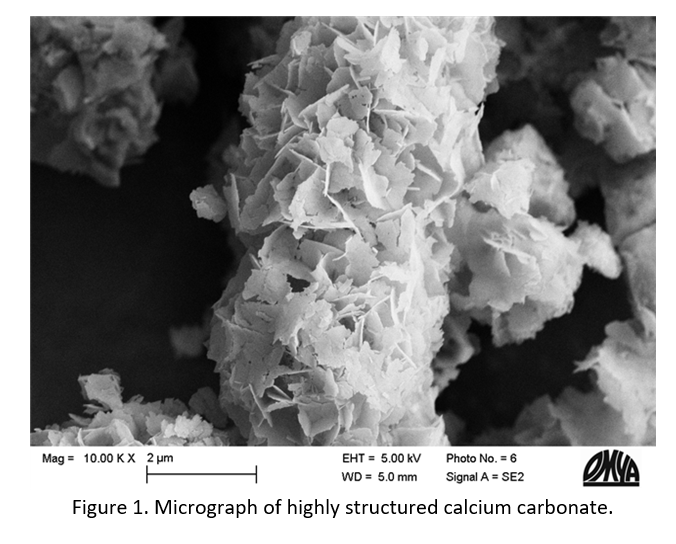

Omyapharm 500-OG is a highly structured mineral based on calcium carbonate and tribasic calcium phosphate, manufactured via a recrystallization process (Figure 1). The final particles are characterized by an external lamellar structure and an internal network of interconnected pores. In contrast to other porous excipients, Omyapharm 500-OG has a lamellar morphology that facilitates the production of granules by dry granulation without the use of a binder. This structure provides plenty of surface contact points among the particles, ensuring interlocking during dry granulation in roller compactors, which results in stable mechanical binding.

High compactibility

Researchers compared the compactibility properties of this highly structured calcium carbonate against other common excipients.1 Tablets manufactured with the excipient in powder and granule form were compared with conventional calcium carbonate, mannitol or microcrystalline cellulose (MCC) tablets. At low compression forces, the tensile strength of tablets formulated with Omyapharm was higher than that of tablets formulated with mannitol or calcium carbonate, and was comparable to that of tablets formulated with MCC. They also had a higher porosity than those containing the other excipients. With the mineral excipient in the formulation, tablets had comparable or higher hardness than other formulations at lower compression forces. This allowed their porosity to remain higher than 50%, and provided a large volume of voids for accommodating APIs.

Enhanced mouthfeel

Among healthy volunteers, ODTs formulated with Omyapharm 500-OG were well accepted and disintegrated rapidly.2 Additionally, despite the high mechanical stability of the tablets, the high porosity required to absorb the liquid necessary for disintegration was preserved. These findings led to the conclusion that the mineral excipient is highly suitable for ODT dosage forms and can impart a pleasant mouthfeel.

Fast disintegration

Using a tensiometer to determine residence time, another research group analysed the disintegration kinetics of 24 different formulations and identified four patterns: type I was considered the ideal behaviour because it resembled the market formulation;3 type II was characterized by very fast water uptake but no disintegration; type III disintegrated in discrete steps, resulting in tablet pieces; while type IV disintegrated only partially. Tablets formulated with Omyapharm and croscarmellose sodium exhibited a type I disintegration pattern, and their residence time was half that of the reference market formulation.

It is the mineral excipient’s direct compressibility into granules without the use of a binder and its high porosity that allow faster water uptake, leading to a disintegration time that is twice as fast as the market reference product. In fact, ODTs manufactured with Omyapharm may disintegrate in less than 10 seconds.

Market potential

Unlike many similar materials, Omyapharm 500-OG has the advantage of being biocompatible. Its composition is basically that of bone mineral: hydroxyapatite and calcium carbonate. It also offers multiple functionalities with simple chemistry, and enables straightforward manufacturing. ODTs manufactured with this mineral excipient do not require cost-intensive production equipment because they can be produced by direct compression. Their high mechanical strength enables the use of regular bottles and blisters as packaging, which reduces the overall cost of production compared to other ODT technologies. Bearing these advantages in mind, Omyapharm may be considered a promising excipient for dry oral dosage forms, particularly ODTs.

References:

- Stirnimann T et al. Int J Pharm 2014;466:266-75.

- Wagner-Hattler L et al. Int J Pharm 2017;534:50-59.

- Stirnimann T et al. Pharm Res 2013;30:1915-25.

Author:

Carolina Diaz Quijano PhD, Head of Technical Services Consumer Goods, Omya International AG, Baslerstrasse 42, 4665 Oftringen, Switzerland

E: info.pharma@omya.com