Cosmetics & Personal Care

Why feeling the cold makes sense for laundries 1st February 2019

By David Aveyard, Operations Director of Christeyns UK

David Aveyard, Operations Director of Christeyns UK discusses how ozone is helping commercial and on-premise laundries.

David Aveyard, Operations Director of Christeyns UK discusses how ozone is helping commercial and on-premise laundries.

Employed as early as 1906 to treat the water supply in Paris, and used today in some processes for producing bottled water, ozone is known for its bleaching action and ability to kill bacteria and viruses. It also has a practical, money-saving application in laundry operations. Systems that generate ozone and inject it into laundry water can dramatically reduce hot water use in large laundry operations, as well as reducing the amount of cleaning chemicals used and producing cleaner, brighter linens and clothing.

Ozone is formed when oxygen comes into contact with highly charged electrical energy. When this occurs, it breaks the molecular bond of the O2 into single oxygen atoms. These atoms then bond to remaining oxygen molecules (O2), creating ozone (O3). It’s the third oxygen atom in ozone’s molecular makeup that makes it such a powerful cleaning agent.

When ozone gas is introduced to an environment with bacteria, mold or any other organic material, it gives up one of the oxygen atoms in its structure to oxidize or destroy that material. Once the third oxygen atom is used to oxidize an organic or inorganic contaminant, there is only an oxygen (O2) molecule left. This is one reason why ozone is preferred as an oxidant to various chemicals, because it does not leave any type of residual chemical.

To obtain the ozone, a laundry ozone generator replicates the naturally occurring gas and then introduces a low concentration into the water under pressure. As the ozone molecule is unstable, it can not be packaged and must be produced, on-demand, on site. It cleans, whitens and brightens, all without the use of hot water, before it naturally reverts back to oxygen.

Specialist laundry chemical manufacturer, Christeyns, has succeeded in combining the advantages of ozone properties with the requirements of a commercial wash process with its new Speed-O wash concept. This expertly designed concept goes one step further than just using ozone. Christeyns combines active oxygen (peracetic acid) together with the ozone to create a hydroxyl radical which breaks down soil in the wash.

New chemicals, Speed-O Wash, a detergent, and Speed-O Boost, an alkali booster, have been specifically developed to perform at cold temperatures. By adding surfactants to the detergent, Christeyns has ensured that the detergent is fully active throughout the wash process and not broken down by the ozone; this process will remove both grease as well as other soiling.

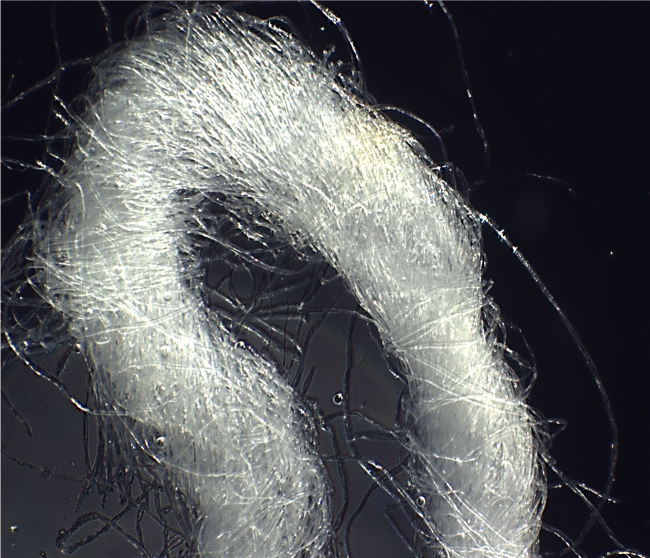

The ozone molecule intervenes in the wash process in various ways. Ozone opens the fibre structure (pictured) and makes the fabric softer and fluffier. The textile thus contains less residual moisture after the washing process, so drying times can be reduced. Ozone also boosts the performance of the laundry chemicals and dirt deposits adhering to the textile fiber are loosened and chemically broken down.

Blanchisserie Nelly, in the Vaucluse region of SE France installed an ozone system in 2014. The laundry has two washing machines, 150kg and 210kg. Between 2014 and 2017 the turnover of the laundry increased by 15%, whilst saving 1 day in terms of productivity.

In a second case study, at the Intercommunal Hospital Centre (CHI) Lys-Hyrome in Maine-et-Loire, the use of ozone has transformed the laundry since its implementation in Spring 2018. The two sites at Vihiers and Chemillé, wash 324 tons of linen annually.

“Ozone has an important oxidizing power: its use has allowed us to lower the temperature of the washing water to 16°, allowing us to reduce our consumption of water and electricity. In addition, it opens the fibres of the fabric and make it softer,” comments Stéphane Gadeyne, hotel service engineer.

By including ozone when laundering commercial quantities of linen, towels and bedding, you need nothing more than cold water, detergent and ozone gas. This reduces costs, makes business more efficient, competitive and cost effective.

An additional benefit is that the laundry room is much cooler in the summer. The decreased need for hot water reduces the work room temperature considerably. The gas does however have a strong smell so the room needs to be well ventilated.

We are confident that using ozone in combination with our specifically developed Speed-O chemicals can make a significant difference to facilities such as care homes, hotels and leisure outlets that manage their laundry in-house. For soft, fluffy, white linen, that is hygienically clean, ozone provides a great value for money solution and has an overall positive impact on the housekeeping task in general.

Author:

David Aveyard, Operations Director, Christeyns, Bradford, Yorkshire, UK

T: +44 (0) 1274 393286

http://www.christeyns.com

David Aveyard, Operations Director, Christeyns, Bradford, Yorkshire, UK

T: +44 (0) 1274 393286

http://www.christeyns.com