Materials Science

Compliant by Design 12th November 2018

By Ignacio Buezas Sierra, Business Development Manager at ELIX Polymers

Two new grades of thermoplastic polymers have been designed for compliance, helping to address the challenges faced by OEMs need

Two new grades of thermoplastic polymers have been designed for compliance, helping to address the challenges faced by OEMs needing to comply with safety-of-use regulations, explains Ignacio Buezas Sierra, Business Development Manager at ELIX Polymers.

Regulatory compliance has caused real headaches to many industries in a growing number of segments in recent decades. The need to adapt products and processes, in order to ensure compliance, has never demanded so many resources, or so much understanding of the complete value chain. This scenario is unlikely to change within the current and near-future international landscape.

Polymer producers have been affected primarily by limitations in the use of specific raw materials. Many different tests have been created and implemented to certify the compliance of products, according to different regulations. Nevertheless, at the end of the day, legal responsibility lies with the original equipment manufacturers (OEMs) that bring the final products to market. This situation generates a number of risks and uncertainties across many processes within these companies.

To address this complex issue, ELIX Polymers has launched a new product line that places a focus on regulatory compliance. Several acrylonitrile butadiene styrene (ABS) grades from the standard portfolio have been adapted and analysed, and the information collected during this process could help customers to design, produce and qualify their final parts with greater confidence. The new product line comprises two grades, addressing the levels of safety that OEMs are looking for, namely a food contact ‘TF grade’ and a ‘Chemical Compliance grade’.

The TF grade (ELIX ABS M545TF) represents the highest compliance level, and offers a high-flow ABS material able to provide very high gloss and balanced mechanical properties. ABS M545TF has been developed to offer compliance with standards close to those required in the medical industry, even if normal applications are in the consumer industry. For example, it may be used for personal care devices (toothbrushes, depilatory devices) which are borderline to be considered as medical devices, due to the type of use and contact with skin. ABS M545TF has also been tested for the fulfillment of other directives, such as food contact regulations. Therefore, customers have reference values to work with, and this can help them to find the best way to process and manipulate the material to meet required safety standards.

OEMs that are working globally often face different levels of regulatory requirements for some type of products, depending on the region where they are selling. For those looking to simplify their supply chain and material homologations, ABS M545TF offers an interesting opportunity as it complies with the most stringent regional regulations related to the safety-of-use of polymeric materials.

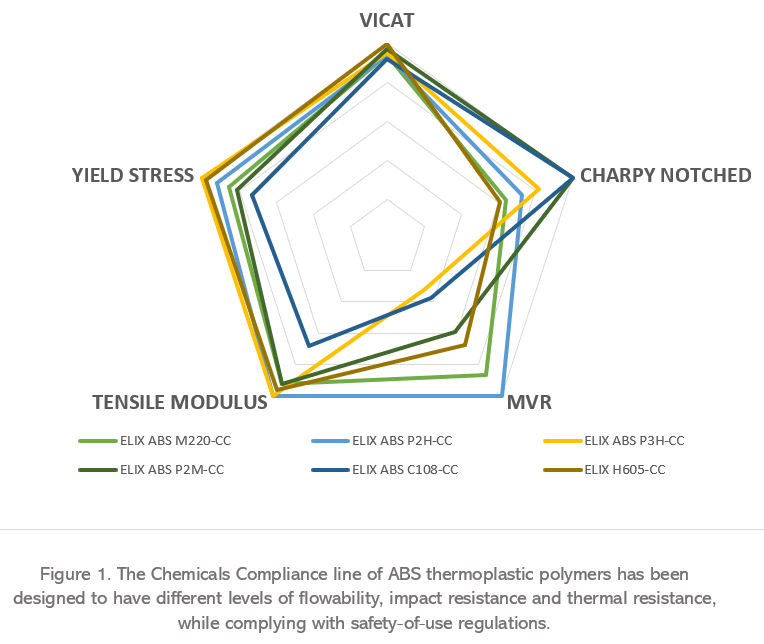

The second group of products, Chemical Compliance, has been formulated for most applications where safety-of-use regulations are involved. It includes several products with different levels of flowability, impact resistance and thermal resistance (Figure 1):

- P2H-CC has a very high flowability and medium impact resistance; high gloss for housings, kitchenware or any other application with aesthetic requirements

- P2M-CC has medium flowablity and very high impact resistance; also high gloss for applications with aesthetic and impact resistance requirements

- P3H-CC is a medium-flow material with improved chemical resistance compared to standard ABS, with well-balanced mechanical properties

- M220-CC is a high-flow material with balanced mechanical properties targeted for self-colouring applications

- H605-CC is a high flow and high thermal resistance grade targeted for applications requiring a VICAT value above 100oC

- C108-CC has a high rubber content for applications with very high impact resistance requirements, both at room and low temperature.

In order to ensure that customers can use these ABS grades with confidence, all TF and Chemical Compliance grade polymers have been carefully developed to ensure any colour or additive formulations fulfill the appropriate regulatory requirements. When a colour or special additive package is implemented in one of these products, the product stewardship department (responsible for the compliance of ELIX products) works together with the colour laboratory to guarantee that the use of these components does not create compliance risks. ELIX Polymers has a database of more than 300 colours that are approved for use in applications where food contact, or even contact with skin, are required.

In conclusion, OEMs requiring thermoplastic polymers for injection molding, part production and 3D print manufacturing are under increasing pressure to comply with safety-of-use regulation, which include regulations pertaining to raw materials and impurities. Use of polymers that have been designed for compliance may help address some of the challenges faced by OEMs needing to comply with these regulations, reducing some of the risks and uncertainties and allowing them to manufacture their products with greater confidence.

Author:

Ignacio Buezas Sierra, Business Development Manager at ELIX Polymers, Ctra Vilaseca a La Pineda, 43110 La Canonja, Spain

T: +34 977 83 54 00

www.elix-polymers.com