Agrochemicals

Innovation in the ag-chem market 27th July 2018

By Glenn Carroll, Global Market Manager at Vertellus

Glenn Carroll, Global Market Manager at Vertellus explains how the company is continuing its strategic growth in crop protection c

Glenn Carroll, Global Market Manager at Vertellus explains how the company is continuing its strategic growth in crop protection chemicals.

Vertellus, a global manufacturer of fine and specialty chemicals, continues to invest in assets to expand its ag-chem technology and manufacturing capabilities. A long-time leader in developing and supplying products to the ag-chem market, Vertellus’ strategy is to add capabilities and resources to offer a broader portfolio of heterocyclic chemistries – pyrazoles and triazoles for example. Chemicals Knowledge caught up with Vertellus’ Global Market Manager Glenn Carroll, to discuss Vertellus’ initiatives to innovate in the ag-chem market.

What chemistries and technologies has Vertellus recently added to its portfolio and how do they complement the company’s legacy chemistries?

Glenn Carroll: Vertellus’ roots go back to 1867 and, since its earliest days, the company has developed chemistries across the pyridine value chain. This expertise spans across a broad range of heterocycles which are used by customers in the crop protection and life science areas. Vertellus is expanding capabilities in hydrazine chemistry to include manufacture of hydrazine containing intermediates and active ingredients (AIs) at its Halebank, UK site. Vertellus’ investment in a broader portfolio of chemistries helps manufacturers of fungicides, herbicides, insecticides—and others in the ag-chem space—focus on their core expertise in discovering new AIs while continuing to outsource development and manufacturing activities.

What core chemistry technologies does Vertellus offer?

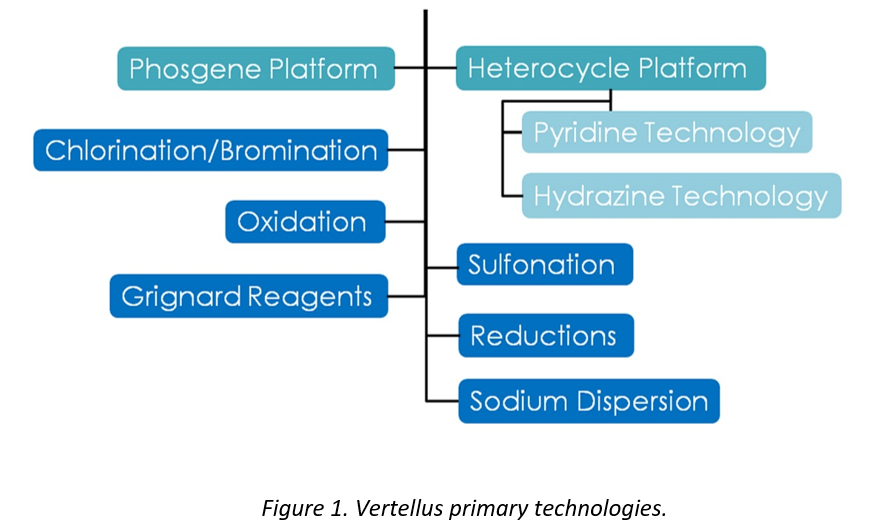

Glenn Carroll: Vertellus offers platforms in heterocyclic chemistry and phosgene technology as well as supporting capabilities including chlorination/bromination, sulfonation, oxidation, reductions, Grignard reagents and sodium dispersion (Figure 1). The heterocyclic platform is supported by pyridine and hydrazine technologies. While pyridines have always been a part of Vertellus’ core offerings, recent additions, acquisition and continuing site upgrades bring to Vertellus’ customers a broader range of technologies used to manufacture intermediates, advanced intermediates and active ingredients.

How did the company transition from pyridines into offering broader chemistries?

Glenn Carroll: In Q4 2014, Vertellus purchased Pentagon Chemical, a highly respected regional CMO. The acquisition provided a strong asset base that included phosgenation capabilities, and the site has been continually upgraded though the addition of new capabilities such as hydrazine. The location’s multi-product protocol allows a wide range of chemistries and functional transformation to be practiced.

What toll or custom manufacturing services does Vertellus offer?

Glenn Carroll: Ag-chem innovators must always choose whether they want to make an intermediate or AI internally or outsource production. For those who opt to outsource, we’re seeing a shift from traditional CMO operations where a product is manufactured based on a technical package provided by the customer; or even a CDMO relationship where suppliers are involved earlier in optimization of the process. Increasingly, we’re being asked to help develop syntheses earlier in the process. Vertellus’ experience in developing syntheses and optimizing processes for its “own products” transcends into assisting customers at earlier stages in the development of their AIs.

Where does Vertellus manufacture its ag-chem products?

Glenn Carroll: Although Halebank is the primary site for AI manufacture, we have multi-works assets at other facilities such as Zeeland, MI, USA and Indianapolis, IN, USA. Heterocycles are produced at several facilities depending on the requirements. Hydrogenation is performed at our Zeeland, Michigan, USA site and Indianapolis, USA locations. Vertellus is very proficient at handling extremely hazardous materials as we use phosgene, chlorine, bromine, liquid sulfur trioxide, ammonia and sodium metal to name a few at many different locations.

Although we have a global footprint, our operations maintain a local presence. Vertellus operates 12 locations including six research and development centers. We are headquartered in Indianapolis, IN, USA and have operations in the United Kingdom, China and India. Collectively, these facilities offer chemistries that range from building blocks to advanced intermediates and AIs.

What are special concerns when it comes to the manufacture of AIs in the ag-chem sector?

Glenn Carroll: Vertellus operates all crop protection chemical sites under ISO 9001:2015, or better, to ensure high quality products and services. In addition, the Halebank site has multiple production trains, some of which are dedicated to herbicide manufacture safeguarding against cross-contamination with other products.

In addition to manufacturing, do you offer additional capabilities?

Glenn Carroll: Vertellus offers services and specialized capabilities including environmental, health and safety (EHS), intellectual property protection and solutions to support leveraging raw materials across the supply chain. Pilot facilities in both Zeeland, MI, USA and Halebank, UK support our customers from the laboratory through development to commercialization. Additionally, the regional operations in North America, China, Southeast Asia and India allow more than 850 employees worldwide to be closer to our customers.

How have customers affected Vertellus’ approach to expanding its offerings?

Glenn Carroll: When it comes to partnering with customers, there are both “qualifiers” and “differentiators” and in a competitive marketplace, it’s important not just to meet the qualifying considerations but also offer value that differentiates.

Qualifiers are those non-negotiable factors required to do business. These include a record of HSE excellence from both a sustainability and compliance perspective, consistent quality that provides a license to operate, cost competitiveness when it comes to price, service and continuous improvement; and a trusted relationship inclusive of intellectual property protection. Customers also want a supplier who can consistently meet supply needs and they are looking for partners who can demonstrate a record of performance.

Differentiators distinguish a company from all the others in its space. At Vertellus, we place a heavy focus on technical capabilities focused on innovation and advancing the learning curve. Our partnerships with world-class universities support our efforts to continually advance technologies. Another differentiator we focus on is responsiveness. Customers expect agility and the ability to adapt quickly to changes in the market and in their business.

Looking broadly at the ag-chem sector, what conditions are influencing how Vertellus approaches the business?

Glenn Carroll: There are several macro-trends driving ag markets today. In many ways, AIs in the ag-chem are becoming increasingly similar to AIs in the pharma space as molecules become more complex. Providing a broader range of capabilities enables a CDMO to conduct more synthetic stages for their customer.

Other macro issues relate to global trends. Crop growers must meet growing demand for animal protein driven by greater levels of affluence among consumers desiring improved nutritional diets. And there is the ongoing innovation required to combat the adaptation that occurs as weeds, insects and fungi develop resistance to particular ingredients requiring new blends and molecules.

The environmental concerns occurring in China have created a disruption in many supply chains which has caused customers to look for new alternatives creating a need for alternative supply.

Is Vertellus considering additional acquisitions?

Glenn Carroll: While today’s environment provides abundant opportunity for organic growth, Vertellus’ will continue to look for attractive acquisitions that complement our chemistries and capabilities.

Contact:

Glenn Carroll, Global Market Manager at Vertellus, 201 N Illinois Street, Indianapolis, IN 46204, USA.

E: gcarroll@vertellus.com